山东中航泰达复合材料有限公司

联系人:陈经理:13395365635

联系人:张经理:13905360936

电 话:0536-6217224

地址:山东省诸城市高新技术产业园

(密州东路与芦河大道交叉口东400米路南)

Infomation

咨询电话:13395365635

咨询电话:13395365635

2019-10-15

2019-10-15

| SHANDONG 山东中航泰达复合材料股份有限公司 ADD: No.7800, East of Mizhou Road, Zhucheng, City of |

PLANNER DATE:

2016-06-07

-----Composite Autoclave

NO: ZTDCN20160607

(Pictures are only for reference information, take

practicality as standard)

目 录

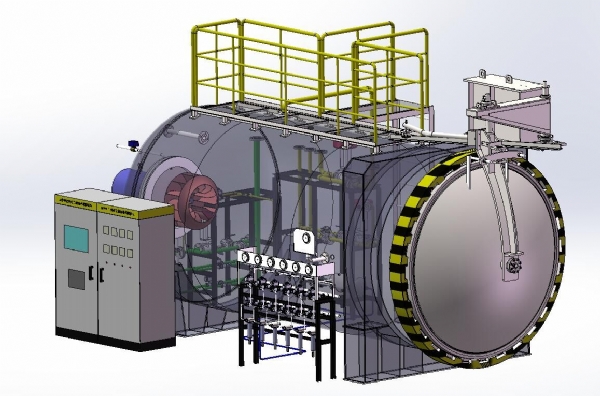

1. 3D SKETCH 热压罐3D制图

2. LISTED SPECIFICATIONS 热压罐规格表

3. SPECIFICATION

IN DETAIL基本参数

4. SYTEM PROFILE 系统介绍

-----------------4.1

Flange cap罐门

-----------------4.2

Body 罐体

-----------------4.3

Insulation 保温

-----------------4.4

Loading design承载设计

-----------------4.5

Motor air flow control风机循环单元

-----------------4.6 Heating control 加热单元

-----------------4.7

Cooling system压力单元 (Offer not include the fittings noted in red)

-----------------4.8

Pressure control冷却单元((Offer not include the fittings noted in

red))

-----------------4.9

Vacuum system真空单元

-----------------4.10 Temperature control温度测量单元

-----------------4.11 Safety guarantee part安全系统

-----------------4.12 Maintance platform维护平台

-----------------4.13 Automatical operation system自动控制单元

-----------------4.14 Operation environment环境要求

5. DUTY FOR BUYER AND SELLER分工

6. SELLER SITE CONFRIM验收

7. DELIVERY运输

8. PAYMENT付款

9. GUARANTEE质保

10.

CONFIGURATIONS LISTED 配置表

1. DESIGN SKETCH 3D 热压罐3D制图

1) WORK SPACE : 2000MM *4000MM

2) VACUUM PORTS 32 NOZS

3) DESIGN FOLLOWING RULES OF “CHONHUNTEDA ”

4) PRESSURE EQUIPMENT DIRECTIVES ASME

2.LISTED SPECIFICATIONS 热压罐规格表

2.1 Main specification主要技术参数 | UNITE单位 | CONTENT内容 | |

DOOR CAP门的数量 | PCS/个 | 1 | |

INTERIOR DIA使用内径 | mm | 2000 | |

WORK LENGTH使用长度 | mm | 4000 | |

WORK PRESSURE工作压力 | MPa | 1.1 | |

WORK TEMPERATURE工作温度 | ℃ | 180 | |

DESIGN TEMPERATURE设计温度 | ℃ | 200 | |

BODY MATERIAL罐体材料牌号 |

| Q345R | |

INTERIOR INSULATION保温形式 |

| INTERIOR内保温 | |

HEATING 加热方式 |

| Electrical | |

COOLING MEDIUM冷却方式 |

| Water水 | |

USAGE用途 |

| Composite复合材料 | |

LOADING WEIGHT负载材料重量 | Kg | 5000 | |

TEMPERATURE RISING RATE升温速率 | ℃/min | 0.1-3 | |

INITIAL TEMPERATURE加热起始温度 | ℃ | RT | |

COOLING RATE降温速率 | ℃/min | 0.1-3 | |

COOLING TEM. LIMIT降温终止温度 | ℃ | 60 | |

TEM. UNIFORMITY 温度均匀性 | ℃ | ±2℃(NON-LOADING空载) | |

THERMORCOUPLE NOZS. 热电偶数量 |

| 8 | |

EXTERIOR SHELL TEM.罐体表面温度 | ℃/min | 室温+20℃,局部不超过60℃ +20 room temperature, non - over than | |

PRESSURE CONTROL ACCURACY压力控制精度 | MPa | 0.02Mpa | |

PRESSURE RISING RATE升压速率 | MPa/min | 0.1 | |

PRESSURE RELEASE RATE泄压速率 | MPa/min | 0.1 | |

SILENSER GRADE消音器排气噪音 | dBA | ≦80 | |

| |||

2.2 Basic design基本设计 | |||

ENVIRONMENT WORKING TEMPERATURE 工作温度范围 | ℃/min | 5~40℃ | |

POWER VOLTAGE电源电压 | V | 380V三相五线制 | |

FREQUENCY频率 | Hz | 50 | |

PENUMATIC PRESSURE 控制气源压力 | MPa | 0.8 | |

PENUMATIC REQUIREMENTS控制气源质量 |

| Non-oil, | |

CIRCULATION WATER PRESSURE循环水压力 | MPa | 0.3 | |

| |||

2.3 Air circulation空气循环系统 | |||

AIR FLOW风道类型 |

| Circle 环型 | |

MOTOR QUANTITY风机数量 |

| 1 | |

MOTOR POWER风机功率 | KW | 30 | |

AIR 额度风量 | m3/h |

| |

|

|

| |

2.4 Heating system加热系统 | |||

HEATING 加热方式 |

| ELECTRICAL | |

COILS NOZZS加热器数量 | 个 | 1 | |

COIL MATERIAL加热器材料 |

| Stainless | |

HEATING POWER加热功率 | KW | 150 | |

|

|

| |

2.5 Cooling system冷却系统 | |||

COOLING MEDIUM 冷却方式 |

| Water水 | |

COOLER NOZS冷却器数量 | SET/个 | 1 | |

COOLER MATERIAL冷却器材料 |

| Stainless | |

|

|

| |

2.6 Pressure system供气系统(选配 By Customer) | |||

GAS TYPE气体种类 |

| 空气Air | |

GAS PRESSURE供气压力 | MPa | 1.2MPa | |

AIR COMPRESSOR空压机 |

| xxKW | |

冷干机 |

| 与空压机配套 | |

|

|

| |

2.7 Circulation water循环水(选配 By Customer) | |||

WATER GRADE水质 |

| SOFT | |

PUMP循环水泵 |

| 30m3X2 | |

WATER TANK水箱 |

| 10m3 | |

CONDENSER冷却器 |

| 300000Kcal | |

|

|

| |

2.8 Vacuum sytem真空系统 | |||

VACUUM PORTS NOZS.真空路数 |

| 32 | |

LIMIT VACUUM GRADE极限真空度 | Mpa | -0.098MPa | |

VACUUM MOTOR真空泵种类 |

| Rotary | |

|

|

| |

3. SPECIFICATION IN DETAIL基本参数

1)Temperature:Maximum working temperature: 180ºC

温度:最高工作温度:180ºC

3)Heating rate:0.1‐3ºC/min based on average air temperature from ambient to the maximum temperature

with empty load.

升温速率:0.1‐3ºC/min,基于空载下从室温到最高工作温度的平均升温速率

4)Cooling rate: 0.1‐3ºC /min based on average air temperature from maximum temperature to 60ºC with empty load. 冷却速率:0.1‐3ºC/min,基于空载下从最高工作温度到 60ºC的平均降温速率

5)Steady‐state temperature control accuracy: ± 2ºC

稳态控温精度:± 2ºC

6) Pressure:Maximum working pressure: 1.1MPa

压力:最大工作压力:1.1MPa

7)Pressurization rate: 0-0.8MPa maximum time 15min

升压速率: 0-0.8MPa最大用时用15分钟

8) Depressurization rate: 0.1MPa/min average rate from the maximum pressure to 0

降压速率:0.1MPa/min平均速率,从最大工作压力到 0

9) Steady‐state pressure control accuracy: ±0.014MPa

压力控制精度:±0.014MPa

4. SYSTEM INTRODUCTION系统介绍

4.1 FLANGE CAP罐门

1)Flag swing. Hydraulically operated door with sideward open.

液压侧开门罐门装置.

4.2 BODY罐体

1)Adopt Q345R mid-steel采用Q345R制造

2)Paint:Econoclave will be primed and painted color according to customer required, here it is cool-gray in paint

喷漆:热压罐将会喷有防锈底漆以及根据用户要求喷上面漆。

4)Approximate shipping weight:20,000 KG.

预计运输重量:20吨

4.3 INSULATION保温

1)Interior insulation struction内保温结构

2)Internal sheet metal: Insulation liner, 201 stailess steel

内衬钢板:201不锈钢护板

3)Insulation:Mineral wool insulation: 120mm.

保温层: 矿棉保温层:120mm厚

4) High density insulation which is environmental material

保温材料为无毒害的高密度环保材料

4.4 LOADING DESIGN承载设计

1)Floor supports rails

地板轨道支撑

2)Loading: 5000 kg

承重:5000 kg

3)Cart: Full length cart with 4000kg loading capability

罐内推车:全长度小车,承重4吨

3)Motor jacket cooling system

外部冷却水套

4)Flow‐switch indication to PC

水流开关报警指示,PC监视

4.6 HEATING CONTROL加热单元

1)Electric heating via inconel (Stailess steel )tubular heaters:

电加热,通过不锈钢加热管加热

2)Heaters mounted back at end of autoclave which moving wheels for easy system maintenance.

加热器固定于热压罐尾部,佩带移动脚轮,整体可移出,有利于日后维护

3)Estimated Heater size: about 150KW

加热器功率:约150KW

4)Two linear regulator for heating power , each unite guarantee heating work efficient and energy saving.

两套调功器控制加热区域,每台调功器线性控制加热过程,可以实现高效加热,节约能源。

5)SSR banks with safety contactor.

固态继电器分级接触器控制

6)Proportional control 0‐100% output

比例控制 0‐100%输出

4.7 PRESSURE CONTROL压力单元

1)Automated Inlet and exhaust valve, stainless‐steel construction

自动进气/排气阀,不锈钢材质

2)Manual exhaust valve, stainless‐steel construction

手动旁路排气阀,不锈钢材质

3)Exhaust silencer (Outside of room be ok)

排气消音器,排气噪音≦80dBA

4)Pressure transducer:2

压力传感器:2个

5)Accuracy: ± 0.25%

精度:± 0.25%

6)Air compressor +Dryer+ Filter

空压机+冷干+过滤器

空压机30KW,4.0MPa,Pressure exhaust 2.2CBM/MIN

4.8 COOLING SYSTEM(Offer not include the fittings noted in red)

1)Stainless‐steel heat exchanger. All internal wetted parts stainless‐steel.

304不锈钢热交换器,所有内部沾湿部件均为不锈钢材质

2) Exchanger mounted below floor for easy system maintenance.

热交换器固定于热压罐尾部,佩带移动脚轮,有利于日后维护

3)Proportional cooling valve for main cooling control. Computer controlled.

计算机比例控制的冷却阀

4)Air spray and Mist water valves for trim cooling control. Computer controlled.

计算机控制的气冷、雾冷、与水冷相结合的冷却方式

5)Stainless‐steel water tank 10000L, including,

不锈钢冷却水箱10000L,

6)Auto water makeup valve

自动补水阀

7)Conductivity sensor with auto‐makeup

水位传感器

8) Thermocouple for water temperature monitoring

水温传感器

9)Cooling pump and controls

冷却水泵及其控制

10)Evaporative cooling tower

密闭式冷却塔

11)Tower water pump and controls

冷却塔泵自动控制

4.9 VACUUM SYSEM 真空单元

1)Vacuum source ports: 32 total

抽真空口:32个

2)Each source port will include: 1/2” NPT pipe feed through

每个抽真空口包括:1/2” NPT通孔

3)External manual blocking valve, 3‐piece ball valve, stainless‐steel

外部手动截止阀,3片球阀,不锈钢材质

4)Stainless‐steel tubing, 1/2”

不锈钢真空管,1/2”

5)Block Valve

截止阀

6)Transducer (Same as the pressure sensor)Range: ‐760 mmHg to 0.5MPa

Main vacuum sensor, range ‐760 mmHg to 0.5MPa

真空传感器范围(与压力传感器同品牌规格):‐760 mmHg to 0.5MPa, 真空主管路1只真空传感器,范围:‐760 mmHg to 0.5MPa

7) Accuracy: +/‐ 0.25%

精度:+/‐ 0.25%

8)Vacuum pumps: quantity 2,flow rate of each one: ≥100m³/h. Pumps will be

selectable from control computer for four modes of operation:

真空泵:数量2个,其中每个吸风量≥100m³/h。真空泵能够由控制计算机

9)Vacuum pumps can works on 4 modle:

实现以下四种工作模式:

9.1 Pump #1 operation only 仅使用1号真空泵

9.2 Pump #2 operation only 仅使用2号真空泵

9.3 Both pumps on simultaneously. 两台真空泵同时工作

9.4 Automatic switching between Pump1 and Pump2 every 24 hours. 每隔24小时自动轮换使用两台真空泵。

10)A controlled vacuum level reservoir, and vacuum level is adjustable.

可控真空罐一个,真空度可调

11)All piping and valves of vacuum system are stainless steel.

真空管路中所有管路及阀门均采用不锈钢材质

4.10 TEMPERATURE MEASUREMENT UNIT 温度测量单元

1)Air temperature thermocouples: 2

空气热电偶:2个

2)Ω‐K, including computer monitoring/control.

Ω‐K热电偶 ,计算机监控

3)Part thermocouple jacks: 6

工件热电偶插座:6路

4)Ω‐K, including PC monitoring, data‐acquisition, and control

Ω‐K ,计算机监控和数据采集

5)Measurement precision: +/‐1.1C

测量精度:+/‐1.1C

4.11 SAFETY GUARANTEE PART安全系统

1)Pneumatic, mechanical, and electrical interlocks for door closure

气动、机械、和电气罐门关闭互锁机构

2)High temperature controller with alarm/interlock

超温报警/互锁,超压报警/互锁,

3)Pressure safety relief valve, certified to China GB150-2011 specification

安全阀,中国压力容器认证及中国GB150-2011认证

4)Oxygen monitoring system interlocked to the Econoclave door safety lock to prevent

opening of the door until a safe oxygen level is achieved.

空气零压检测系统,空气压力未到安全压力时,罐门不能打开。

4.12 MAINTANCE PLATFORM 维护平台(No platform while diameter < 2000mm )

None

无。

4.13 AUTOMATICAL OPERATION SYSTEM自动控制单元

1)1 each business PC’s , Current Intel™ processor (Over Intel Core i5), fully loaded

with CPC™,22” Flat screen monitors &1

1台商用计算机,Intel主流最新处理器(Intel Core i5以上),22"平板显示器,预装有全套CPC控制软件,提供按照复合材料固化工艺自动控制热压罐系统。3)UPS, 500VA. Connected to the PLC and both PC computers

UPS,500 VA,给PLC以及计算机供电

4)Allen Bradley switches, buttons, lights, etc.

Allen Bradley开关、按钮、指示灯、报警灯等

5) Power system components

电源系统组件

6)Nema‐12 enclosure Main circuit breakers, standard interrupting

Nema‐12外壳 主断路器

7)Motor starters, 施耐德

电机起动器:施耐德

8) Contactors,施耐德

接触器:施耐德

9)Thyristor/SCR: Chromalox

可控硅:Chromalox

10)HP彩色商用打印机

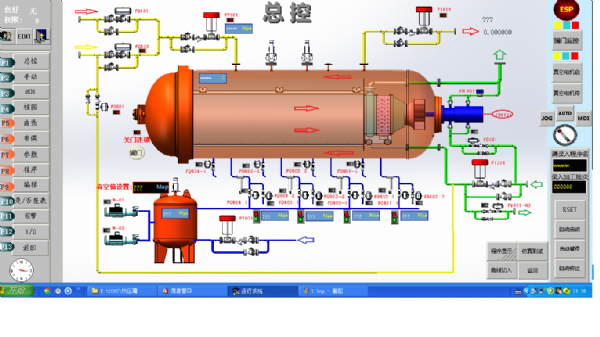

13.1 Main control scenes showing details of autoclave running

主控界面,可显示设备总状态

13.2 Data view details on view scenes to show all ports information

数据显示界面,可形象显示各路数据

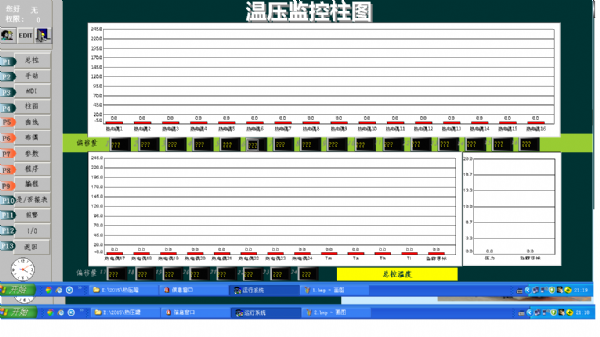

13.3 Temperature sensors location point and working scenes, view temperature distribution trend of mold

热电偶位置界面,通过设定,可以了解产品模具上的温度分布趋势。

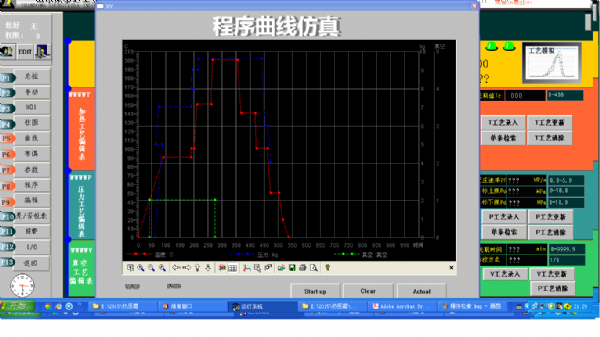

13.4 Simulation view scenes for simulate progress work going on to avoid accidents happened.

仿真纠错界面,编制工艺控制程序后,通过仿真运行,可以防止发生错误。

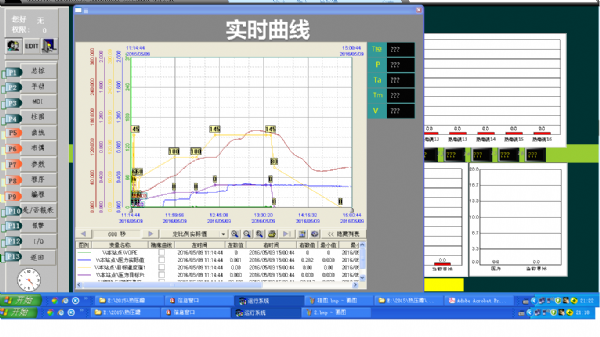

13.5 Immediate

curve scenes to show all running trend interior of autoclave

实时曲线界面,形象显示罐内运行参数的趋势。

4.14 OPERATION ENVIRONMENT环境要求

1)100% environmental material non-toxic

100% 采用环保无毒害材料

Workable environmental 5~45℃, moisture 5~45℃

运行环境5~45℃.湿度≦75%。

5. DUTY FOR BUYER AND SELLER分工

5.1 SELLER RESPONSIBILITY卖方负责:

1)All the electrical cables and wires connection between power cabinet, pressure

vessel and all other autoclDutyave subsystem.

配电柜到罐体及所有热压罐子系统之间的电线电缆连接。

2)All piping of autoclave vacuum, pressure, cooling valve bracket.

热压罐各种真空、压力、冷却水阀架连接及安装的指导;

3)Autoclave’s startup and commissioning

热压罐的开机及调试

5.2 BUYER RESPONSIBILITY买方负责:

1)The following items including materials will be provided by the customer:

以下项目包含材料由用户负责:

2)Connect power cables to autoclave’s main circuit breaker

连接电缆至热压罐主断路器

3)Connect pressure nitrogen and instrument air pipes to autoclave’s points of connection.

连接加压压缩空气管路至热压罐连接口.(压缩空气的压力1.2MPa)

4) Connect exhaust pipe from silencer to outside workshop

从消音器到厂房外排气管路的连接

5)Connect cooling water pipe to autoclave’s cooling valve inlet

连接冷却水管至热压罐冷却阀入口(冷却水温≦30℃,压力≧0.3MPa,提供2路,一路提供风机电机,管径3/4”流量≧4T/h,一路用于罐体内冷却,最大流量≧30T/h。)

6)Assistant work for autoclave’s commissioning

热压罐调试的配合工作

6.1) Autoclave transport works

设备的搬运就位;

6.2) To complete connection and installation works for vacuum, pressure and cooling water system

Under the instruction of seller engineer at site

在卖方的指导下,完成真空、压力、冷却水阀架连接及安装

6.3) Provide material of testing at buyer site

在热压罐调试期间提供试验材料

6 . SELLER SITE CONFIRM验收

1)Econoclave will be tested, inspected, and accepted according Boeing D6‐49327Technical Specification.

热压罐将根据Boeing D6‐49327技术规范进行测试、检查、和验收。

2)The Inspection Report of Econoclave will be provided after acceptance test.

设备完成验收测试时,将会提供热压罐测试报告

3)Autoclave will be fully assembled and quality tested at the ASC Process Systems factory.

热压罐在发运之前会在我公司工厂里完成全部辅助系统的组装

4)Equipment skid/platform is provided and integrated. The skid holds the control panel,

power panel, cooling system, vacuum pumps, and so on.

设备整体成撬,在我工厂里会完成相应辅助系统之间的管线连接,包括控制柜、

配电柜、冷却系统、真空系统等。

5)100% quality testing and commissioning of autoclave at factory prior to shipping.

发运前100%,热压罐会在我工厂里完成全部的质量测试和试运行。

7. CONFIGURATIONS LISTED设备具体构成部件或元件附详细清单说明

NO 序号 | NAME 设备名称 | SPECIFICATIONS 型号规格 | NO. 数量 |

BODY热压罐体部分 | |||

1 | Flange& Door cap 16MnII 罐门和罐口法兰锻件16MnII | DN2500 | 1SET/套 |

2 | Workable size 热压罐有效尺寸(Q345R) | 2000×4000 | 1 |

3 | Air flow channel stailess steel 不锈钢导风罩 | Φ2000×4000 | 1 |

4 | Insulation in stailess steel 不锈钢保温护板 | δ=0.5㎜ | 1 |

5 | Insulation in high density 保温材料 | Ceramic aluminum silicate ceramic folding 陶瓷硅酸铝陶瓷折叠棉 | 1 |

6 | Door style 开门机构 | 液压侧开门 | 1SET/套 |

7 | Gasket of door seal 罐口密封圈 | DN2500 | 1 |

8 | Safety chain interlock 安全联锁装置 | Following design sketch | 1 |

9 | Autoclave safety valve 热压罐安全阀 | A48Y-16C,DN50 | 2 |

10 | Pressure sensor 罐内压力变送器 | 0.1—1.6MPa | 1 |

11 | Water cooling capsule motor 高温密封水冷电机 | x0kW | 1 |

HEATING SYTEM AND TROLLY+WHEEL CART加热系统及罐内外小车 | |||

1 | Electrical heater 电加热器 | xxxKW | 1SET/台 |

2 | Heating unite 加热单元 | Three phases zero switch 固态继电器 | 3PCS/个 |

3 | Loading cart and hingle 进罐小车及高温轴承 | Loaing 4T 承重4T | 1 |

4 | Moving trolly and rail track 罐外小车及轨道 | Loading 5T 承重5T | 1 |

PRESSURE SYSTEM压力系统 | |||

1 | Pressure in pneumatic valve 进气气动球阀 | PN16,DN | 1 |

2 | Pressure release pneumatic valve 排气气动球阀(高温型) | PN16,DN | 2 |

3 | Pipe filter 管道过滤器 | PN16DN50 | 2 |

4 | Manual valve 手动阀门 | PN16DN50 | 4 |

5 | Silencer 消音器 | DN50-PN16-6000 | 1 |

6 | Pipe of air in and release 进排气管道 |

| 1SET/批 |

COOLING SYSTEM冷却系统 | |||

1 | Main water in ball valve 主进水气动球阀 | PN16,DNx0 | 1 |

2 | Side way water in ball valve 辅助进水气动球阀 | PN16,DNxx | 1 |

3 | Manual valve(side way) 手动阀门(旁通) | PN16,DNxx | 4 |

4 | Pneumatic valve 气动球阀 | PN16DNxx(常开OPEN) | 1 |

5 | Pneumatic valve 气动球阀 | PN16DNx0(常闭CLOSE ) | 1 |

6 | Pipe filter 管道过滤器 | PN16DNx0 | 1 |

VACUUM SYSTEM真空系统 | |||

1 | Vacuum pump 真空泵 | XD-100 | 2SET/套 |

2 | (Vacuum) pressure meter (真空)压力表 | Y-100 | 1PCS/块 |

3 | Manual valve 手动阀门 | DNxx | 1SET/套 |

4 | Vacuum testing sensor 测真空传感器 | -1-0.5MPa | 8 |

OPERATION CONTROL AND PARTS,WIRES ECT. 控制系统及控制元件、电线电缆部分 | |||

1 | 德国SIEMENS | PLC200 SERIES系列 | 1SET/套 |

PLC center process unite PLC中央处理单元 | 6ES7 | 1 | |

Data i/o model 数字量输入模块 | | 1 | |

Thermocouple model 热电偶模块 | Simulation 8 input thermocouple 6ES7 | 2 | |

Simulation input model 模拟量输入模块 | Simulation 8 input 6ES7 | 1 | |

2 | Industrial computer 计算机 |

联想 LENOVO | 1 |

3 | Main power breaker 总电源断路器 | Schneider 施耐德 | 1 |

4 | Heating power breaker 加热电源断路器 | Schneider 施耐德 | 2 |

5 | Pump power breaker 水泵电源断路器 | Schneider 施耐德 | 2 |

6 | Vac. pump power breaker 真空泵电源断路器 | Schneider 施耐德 | 2 |

7 | Motor fan power 循环风机电源 | Schneider 施耐德 | 1 |

8 | Motor protector 电动机保护器 | Schneider 施耐德 | 4 |

9 | Alarm 现场报警器 | Schneider 施耐德 | 1 |

11 | Thermocouple 热电偶 | K Patten K型 | 6 |

12 | Control cabinet 控制柜 | 1900mm×800mm×600mm | 1 |

13 | Cabinet interior 柜内其它元器件 | Micro breaker/ relay/button/LED ect. (Schneider 微型断路器、中间继电器、按钮、指示灯等(施耐德) | 1SET/套 |

| 上一条:复合材料结构教学实验室规划及设备配置 | 下一条:热压罐选型 |

网站地图 网站地图 备案号:鲁ICP备16010105号-2 ![]()

![]()